Teamwork

A Costa Sander is the product of highly-efficient teamwork across the company’s international supply chain encompssing the sales, engineering and manufacturing processes, with several years of innovation research and experience, and a vast network of selected suppliers of components from raw materials to semi assemblies.

In this section we detail how Costa sanding machines are built – from the design and production of individual components, all the way to the factory testing, delivery and commissioning in our client's manufacturing facilities.

Application Engineering

In line with its philosophy of global teamwork, Costa avails of a network of regional partners for design and engineering activities supporting our family of sanding machines. This high-tech work is divided across showrooms and support centres covering all continents of the globe.

The design office at Costa headquarters in Veneto, Italy offers top-level competencies as engineering and design, prototyping, manufacturing, system assemblying and testing.

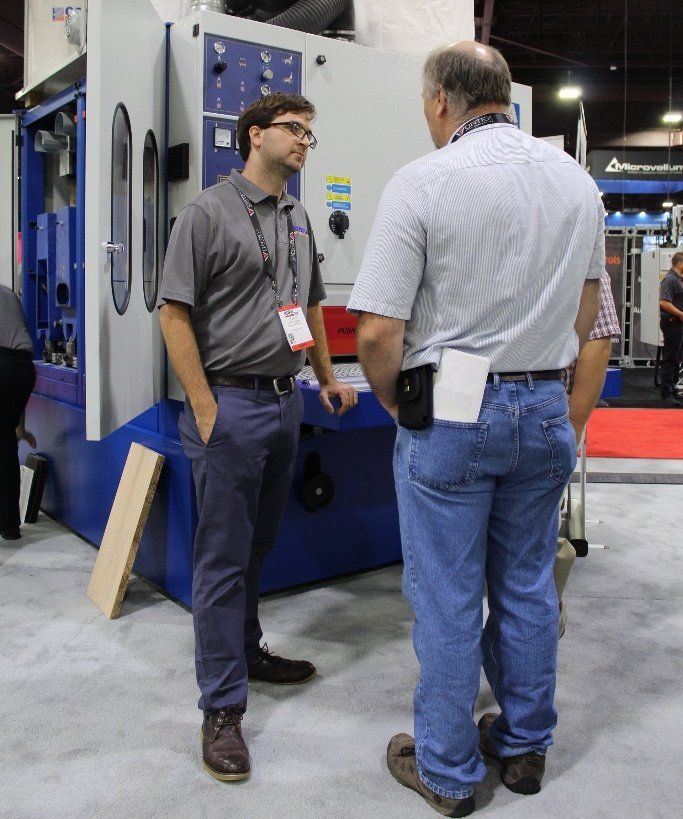

Plant Tour of Manufacturing Facilities

Close-up perspectives of how Costa manages its production and assembly processes as the world’s leading sander manufacturer of Sanding machines are provided for exsiting and perspective customers.